Flip Chip Bonding High-Density Package Substrate

for AP/BB, Controllers

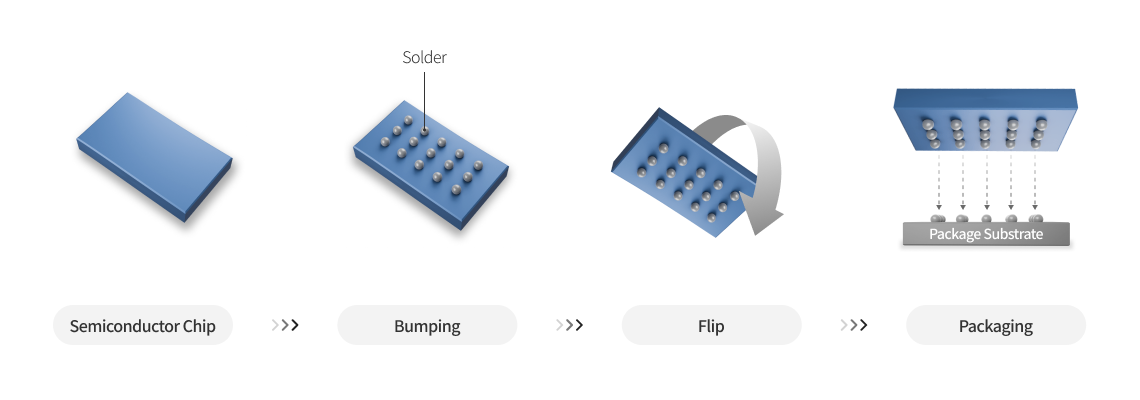

It is called a Flip Chip Chip Scale Package (FCCSP) because it is connected to the substrate in an inverted position

via bumpsratherthan via wire bonding to the semiconductor. It is mainly used for high-performance semiconductors such as

APs (ApplicationProcessors) in mobile IT devices. In addition, compared with WBCSP using gold wires, the process using

Flip Chip can be applied to igh-density semiconductors because the path of electrical signals is shorter, and

a large number of inputs/outputs can be formed.

Main Core Technology

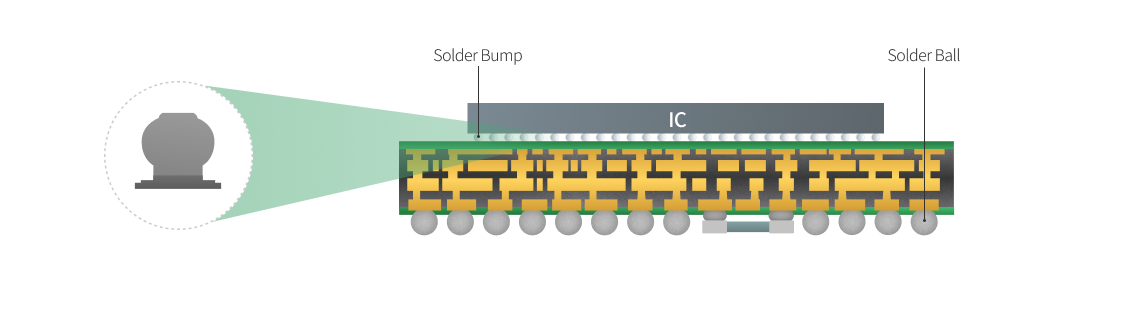

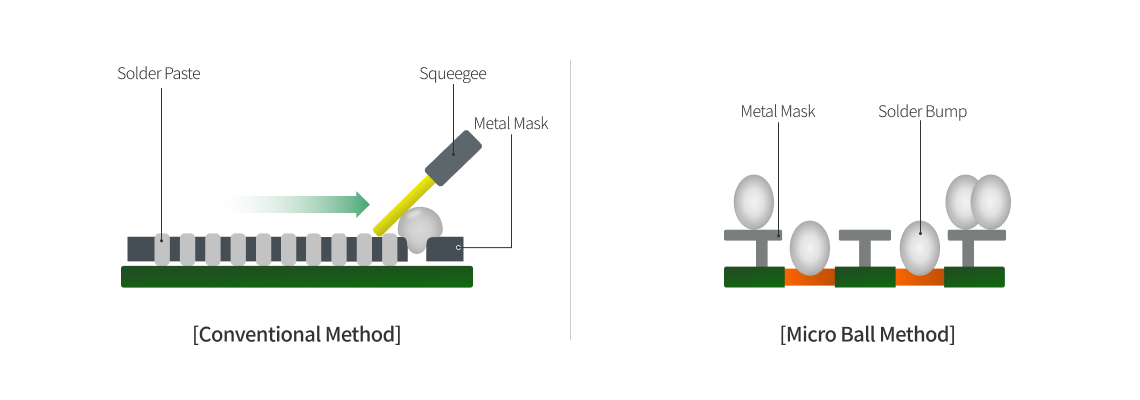

Bumping Structure

Micro Ball Bump Method

- Available for Fine Bump Pitch

- Good for Small Bump Risk

- Good Quality for Bump Characteristics

Substrate Type

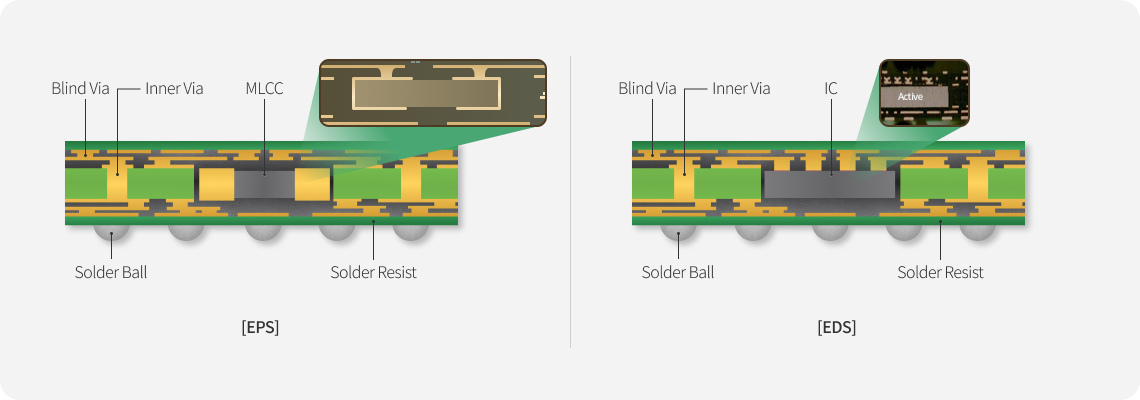

EPS & EDS (Embedded Passive Substrate & Embedded Die Substrate)

EPS/EDS is a substrate with semiconductor passive components, ICs, etc. embedded within the substrate. Passive components are

typically used to stabilize power supply voltage levels. By embedding ICs within the substrate, package size and thickness can be reduced.

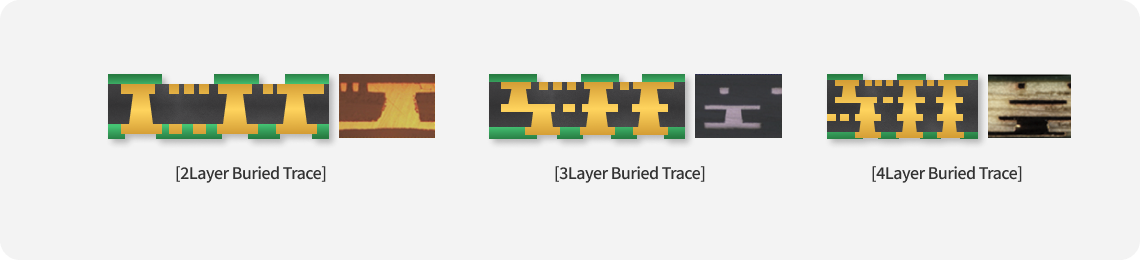

ETS (Embedded Trace Substrate)

ETS is a type of circuit substrate in which the outermost circuit pattern is embedded in insulating material. The substrate has

a coreless structure that enables microcircuits to be realized without increasing cost and facilitates layer-down design (4L → 3L).

In addition, the etching process does not affect the pattern width, allowing precise control of the circuit width.

FCCSP Lineup

Lineup by Specification

| Routing Density | Build-Up Line Width / Space | 7 / 8um (Mass Production) | 6 / 7um (Sample Available) |

|---|---|---|---|

| BVH / Pad Registration | 40 / 67um (Mass Production) | 37 / 60um (Sample Available) | |

| SRO Diameter SR Registration | 45 ± 10um (Mass Production) | 40 ± 10um (Sample Available) | |

| FC Bump Pitch (Peripheral) | 40um (Mass Production) | 35um (Sample Available) | |

| FC Bump Pitch (Area) | 90um (Mass Production) | 80um (Sample Available) | |

| Low Z-Height | Core / PPG Thickness | 40 / 18um (Mass Production) | 35 / 15um (Sample Available) |

| SR Thickness | 10 ± 4um (Mass Production) | 8 ± 3um (Sample Available) |

* um stands for ㎛